Make-break-contact materials [reference data]

Example of CFA500 sectional structure

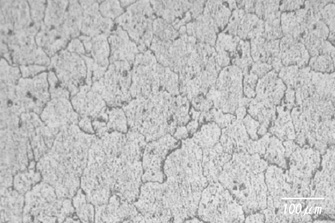

Example of CF510 sectional structure

Figure: Wear characteristics of CFA621 contact (reference)

Figure: Wear characteristics of CF510 contact (reference)

A make-break-contact wears because of the arcs generated while opening and closing. The CF and CFA series offer contact materials with less wear and exhibit performance similar to that of conventional Ag-CdO based contact materials.

Figure: Contact resistance of CF contact (reference)

Contact resistance is one of the important characteristics for make-break-contacts. We provide materials that exhibit low contact resistance even at low contact pressures.