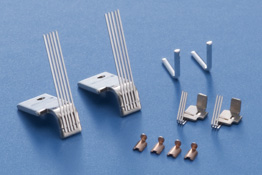

Sliding contact materials

Sliding contacts, being used as brushes and commutators in motors and resistors, are required to have excellent electrical properties as well as superior contact reliability and corrosion and wear resistance. We provide sliding contact materials with excellent spring characteristics, hardness, and other mechanical properties that satisfy the necessary requirements.

TY series and Ag-Pd- and Cu-based alloys

We provide precipitation-hardened types that excel in contact reliability and wear and corrosion resistance, exhibit excellent mechanical properties such as spring characteristics and hardness, and provide high degree of hardness by heat treatment. The TY series offers choices from lines of Au- and Pd-based materials. Ag-Cu-based materials are advantageous in cost and mainly used for commutators.

Physical properties of sliding contact materials (reference)

| Melting point (℃) | Density (g/cm3) | Hardness (HV) | Tensile strength (Soft) (MPa) | Volume resistivity (μΩ・cm) | Application | ||

|---|---|---|---|---|---|---|---|

| Soft | Hard | ||||||

| TY40 | 1030 | 10.5 | 160 | 310*1 | 590 | 11~12 | Brush |

| TY70 | 990 | 10.8 | 190 | 400*1 | 770 | 24~27 | Brush |

| TY100 | 1085 | 11.8 | 200 | 370*1 | 690 | 30~35 | Brush |

| TY200 | 960 | 16.2 | 200 | 330*1 | 540 | 15~21 | Commutator and brush |

| TY300 | 950 | 15.4 | 200 | 340*1 | 650 | 13~22 | Commutator and brush |

| TY401 | 870 | 10.4 | 150 | 250*1 | 600 | 10 | Brush |

| 40Ag-Pd-Cu | 1050 | 10.7 | 200 | 420*1 | 690 | 15~22 | Brush and commutator |

| 30Ag-Pd-Cu | 1050 | 10.5 | 200 | 450*1 | 690 | 11~22 | Brush and commutator |

| Ag-Pd60 | 1385 | 11.4 | 90 | 180 | 370 | 42 | Commutator and brush |

| Ag-Pd30 | 1210 | 10.9 | 70 | 160 | 300 | 15 | Commutator and brush |

| 92.5Ag-Cu | 900 | 10.4 | 80 | 160 | 290 | 2 | Commutator |

- *1Precipitation-hardened product